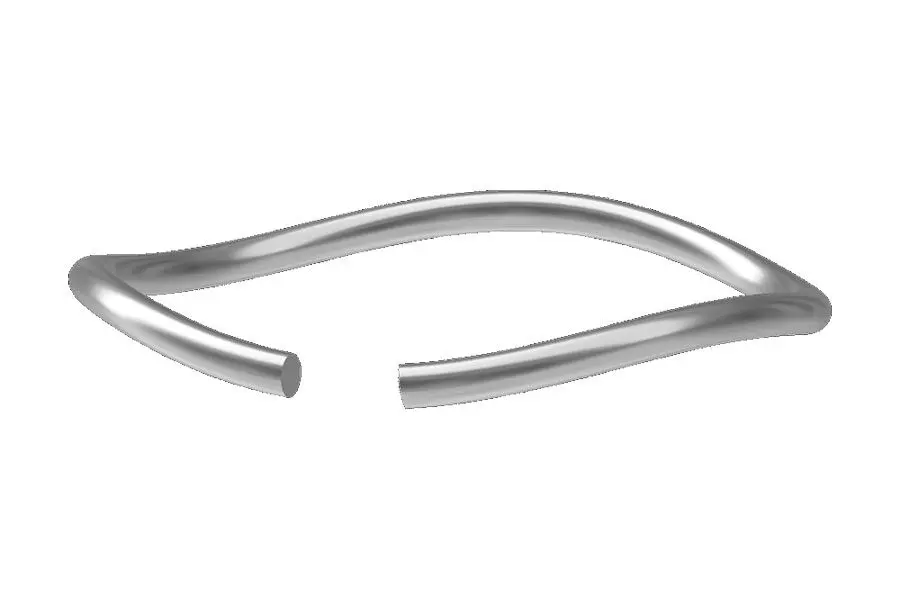

Round-Wire Wave Springs

Strong, accurate, compact and light weight

Designed for use in high load, high rate, low deflection, static or low cycling applications.

If you’re using disc springs or stacks of disc springs, round-wire wave springs could act as a cost effective replacements. These strong and accurate alternative to conventional springs could optimize your application with more accurate loading, radial space savings and less material usage.

Technical Advantages

- Increased loading capacity vs flat-wire wave springs.

- More accurate loading capacity vs. traditional springs.

- Reduce radial space vs traditional springs, flat-wire wave springs and disc washers.

- Less material used in making round-wire wave springs, allowing for a lighter weight product.

- As round-wire wave springs are coiled and not stamped, there’s less waste. This is especially important for exotic alloys and custom parts.

- Standard sizes from 0.5″ through 6″ (12.7 – 152.4 mm)

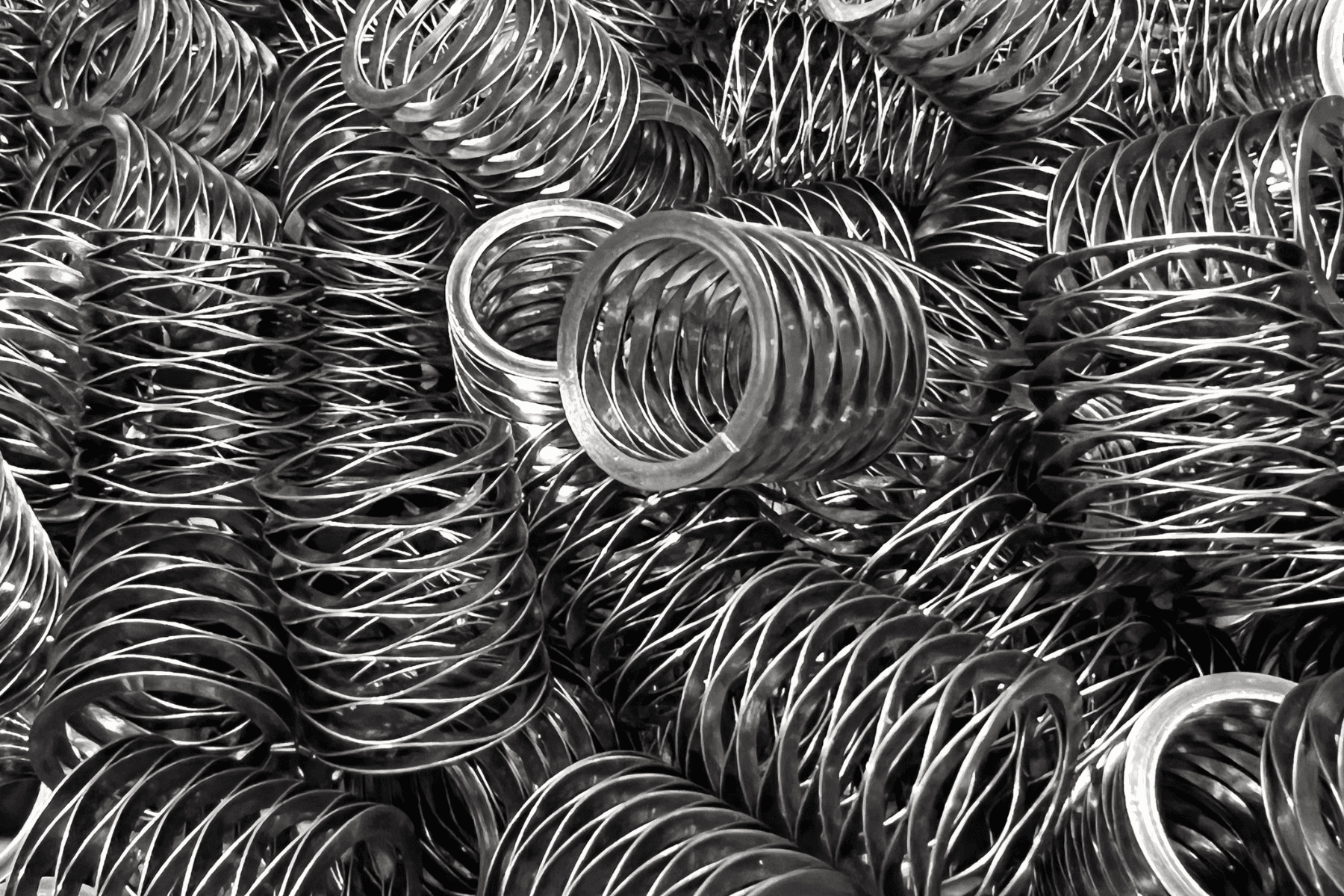

Replace Bellevilles/Disc Springs with Rotor Clip Round-Wire Wave Springs

Traditional Belleville washers or disc springs often fall short in delivering precise, repeatable loads and accurate positioning. Rotor Clip Round-Wire wave springs eliminate misalignment and ensure consistent performance, making them the ideal replacement.

Learn More On Why Round-Wire Wave Springs Are An Ideal Replacement

Application Examples

Round-wire wave springs can be found in applications across every industry. Here are some examples.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.