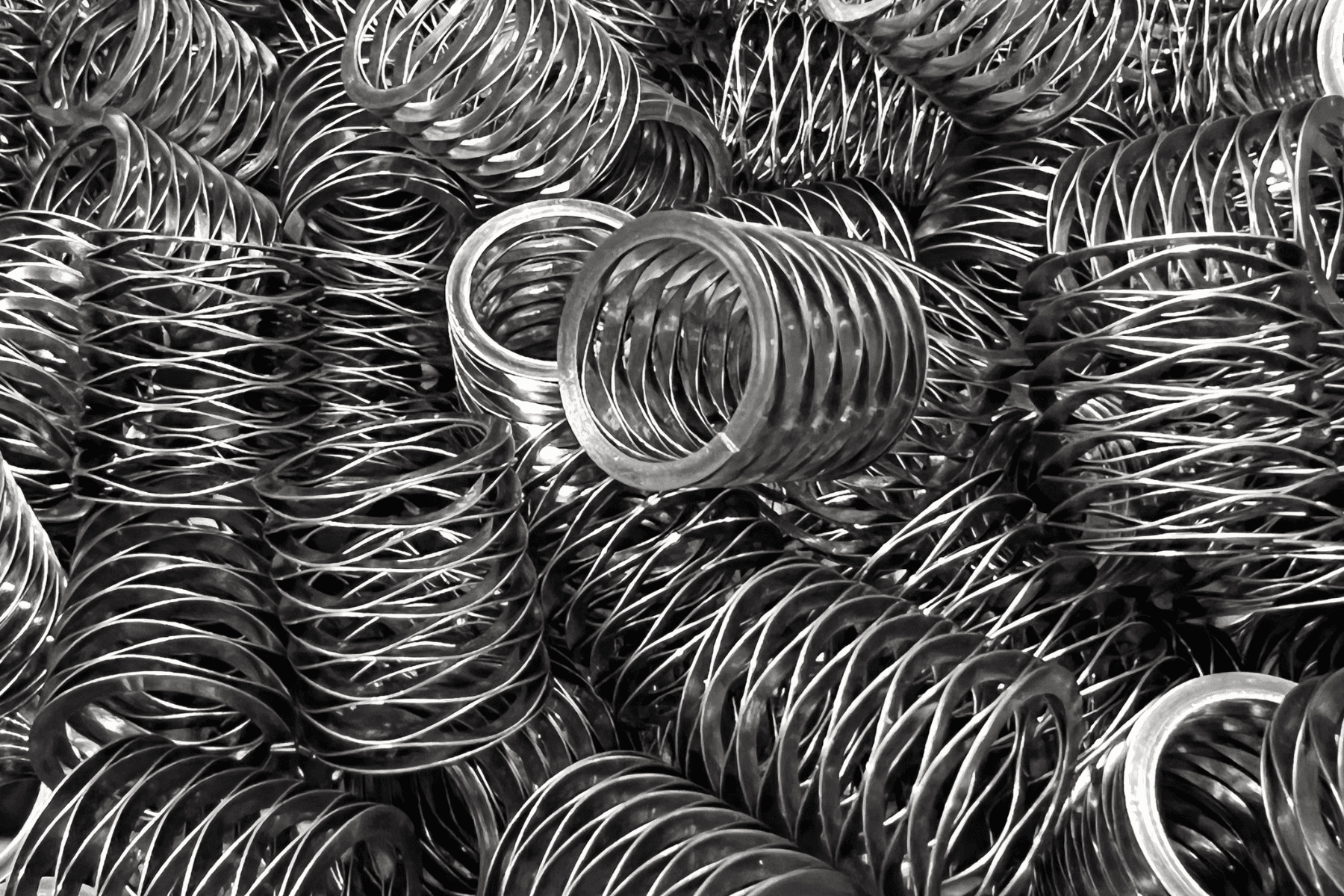

Multi-Turn Wave Springs

Up to 50% axial space savings in your application compared to coil springs.

Multi-turn wave springs typically replace coiled springs or stacks of disc springs and can save up to 50% axial space in an application.

Compact and robust, Multi-Turn Wave Springs can accommodate a wide variety of loads, deflections and diameters. These highly engineered springs can be custom made to exact application specifications, including aspects such as number of waves, wire thickness and end-type configuration.

Technical Advantages

- Multi-turn Wave Springs can save space by up to 50 percent in the axial direction when compared to a coil spring.

- Space savings in radial direction versus other springs with larger diameters.

- One Multi-Turn Wave Spring can replace an array of coil spring.

- Only one spring must be handled, streamlining the assembly process.

- Nearly unlimited range of forces and load capabilities

WSL/WSM/WSR – MULTI-TURN INCH

Used for low to medium force applications with greater travel compared to Single-Turn Springs. Utilizes nearly half the space as helical compression spring while producing the same force.

WSL = Light

WSM = Medium

WSR = Heavy

MWL/MWM/MWR – MULTI-TURN METRIC

Used for low to medium force applications with greater travel compared to Single-Turn Springs. Utilizes nearly half the space as helical compression spring while producing the same force.

MWL = Light

MWM = Medium

MWR = Heavy

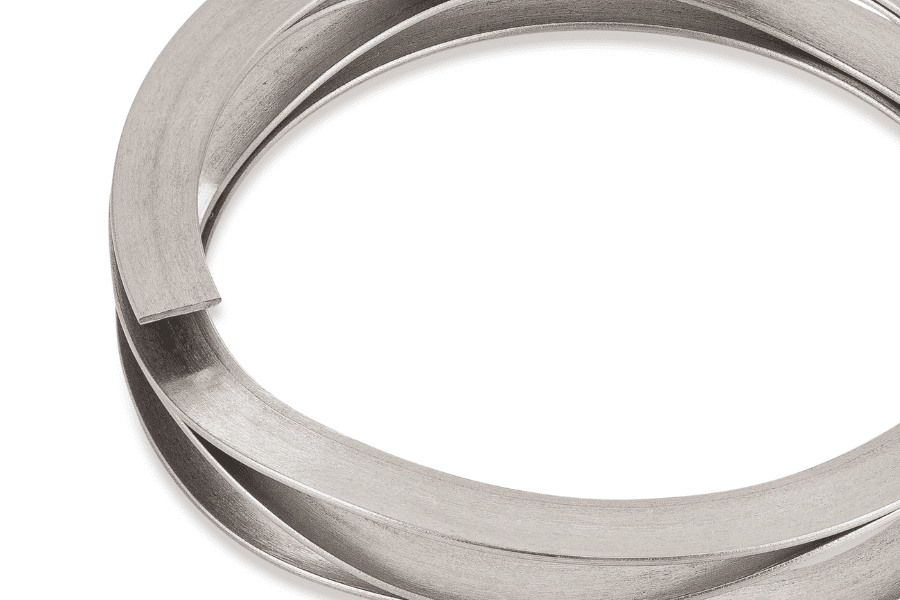

End-Type Configurations

Rotor Clip offer many variations of end type to best suit your application.

Shim Ends

Floating Ends

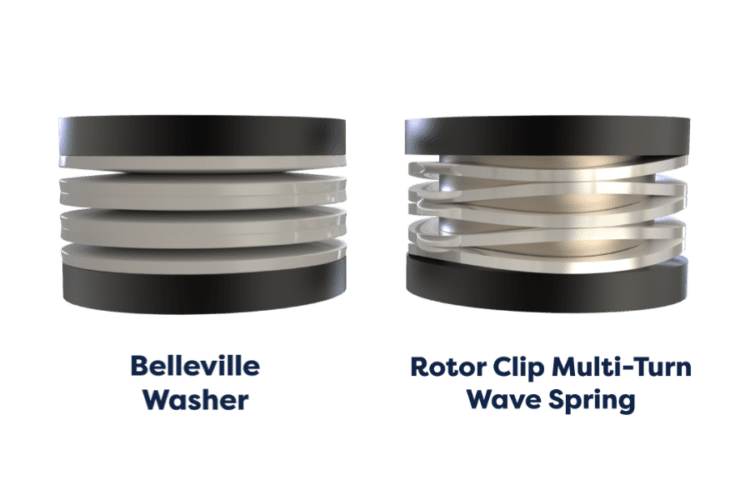

Replace Bellevilles/Disc Springs with Rotor Clip Multi-Turn Wave Springs

Traditional Belleville washers or disc springs often fall short in delivering precise, repeatable loads and accurate positioning. Rotor Clip Multi-Turn wave springs eliminate misalignment and ensure consistent performance, making them the ideal replacement.

Learn More On Why Multi-Turn Wave Springs Are The Ideal Replacement

New Patented InterShim™ Wave Spring

Engineered for the EV Market

The InterShim™ Wave Spring is engineered for reliable performance in demanding applications. Featuring alternating inactive (flat) and active (waved) turns, this patented design withstands torsional loads and high acceleration, ensuring precise and reliable performance when rotational movement is present.

Application Examples

Multi-turn Wave Springs can be found in applications across every industry. Here are some examples.

Downhole Drilling Tool with Multi-Turn Wave Spring

Check Valve with Multi-Turn Wave Spring

Fishing Reel with Multi-Turn Wave Spring

Oxygen Concentrator with Multi-Turn Wave Spring

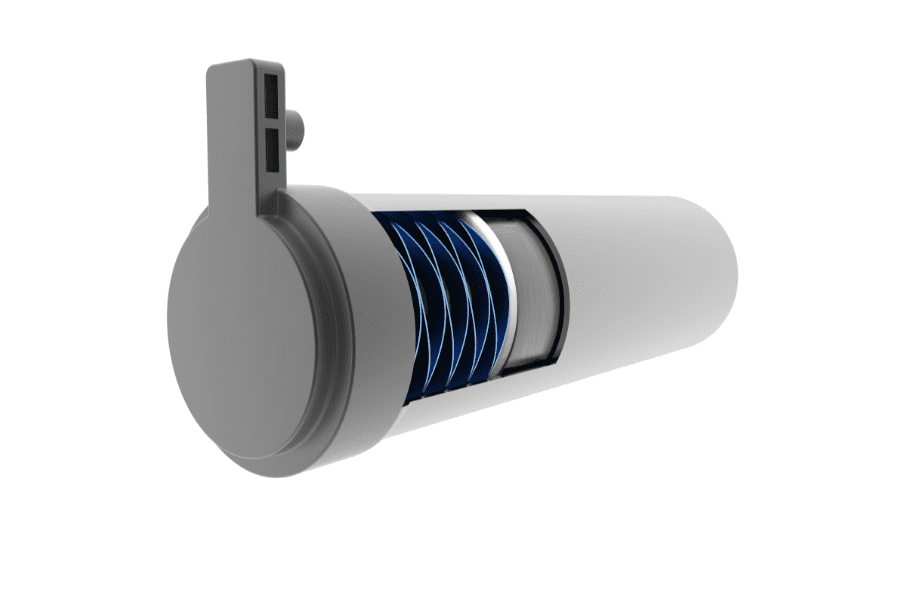

Fluid Filter with Multi-Turn Wave Spring

Car Mirror with Multi-Turn Wave Spring

Simplify Your Assembly with Wave Springs

Rotor Clip Wave Springs offer a simple solution by replacing multiple components, simplifying installation, and reducing the risk of errors. Wave springs deliver the same force and deflection as coil springs, but with the added benefits of space and weight savings.

Watch our latest video to see how a single wave spring can be used to optimize this transmission assembly!

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.