How It Works:

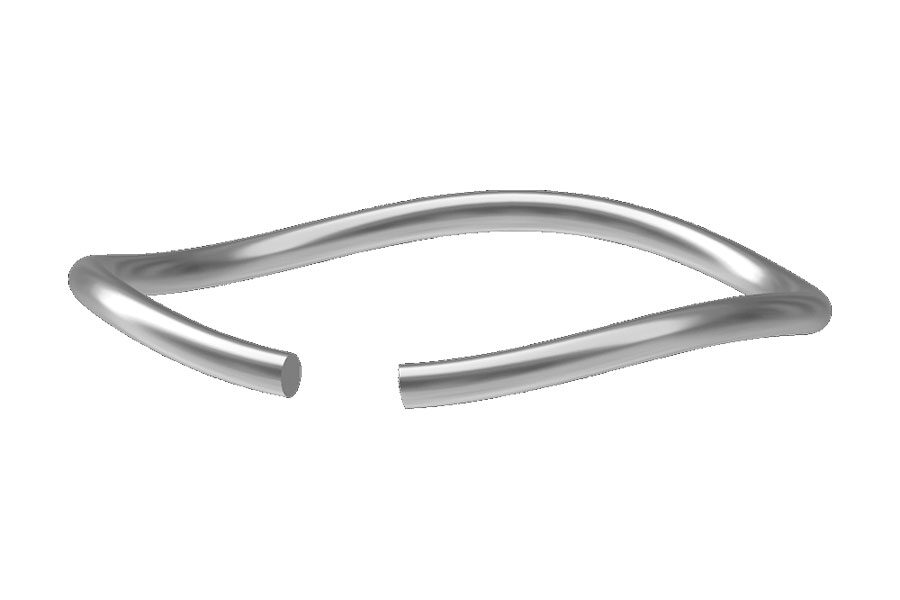

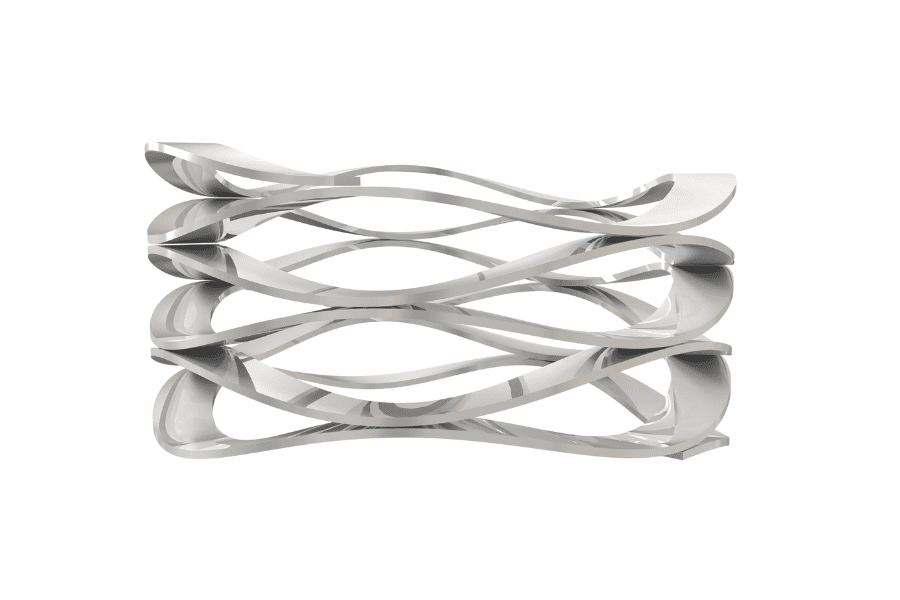

- Design of the turns changes from inactive (flat) to active (waved) in alternation, with an inactive turn always followed by an active turn.

- Every inactive turn in between active turns act like a shim washer between 2 spring elements, preventing the wave trough of a higher-level active turn from moving onto the wave crest of a lower-level active turn due to displacement or circumferential movement caused by torsional loads.

- The turns of the wave spring, arranged with flat or waved shapes, are engineered to smoothly glide against each other. This design prevents the wave spring from collapsing, even when subjected to torsional loads that create relative movement between the active (waved) turns.

- Torsional resistance enhanced by inactive turns between layers.