Quality Control

Certified for industry, awarded for exceeding quality and delivery expectations

Committed to customer satisfaction

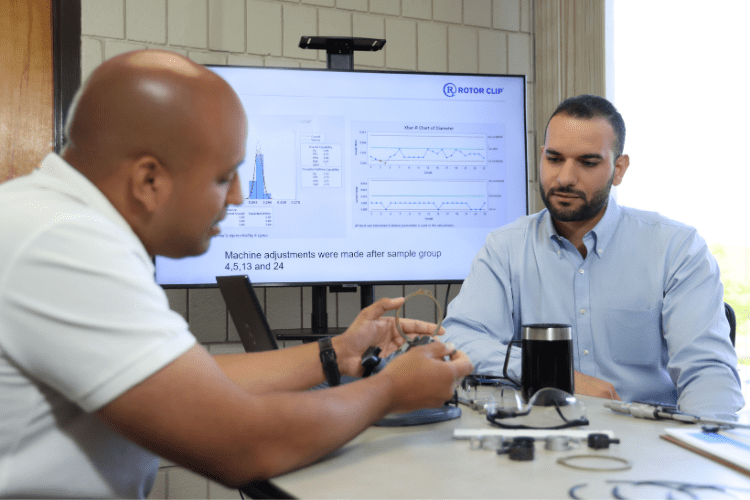

Continuous improvement, certification and stringent, in-house testing

Rotor Clip is dedicated to manufacturing top-quality parts, earning the trust of customers over our long-standing history. We uphold our reputation with certifications including ISO 9001, ISO 14001, IATF 16949, AS9100 and ISO 13485. These internationally recognized quality management systems establish rigorous standards for manufacturers, emphasizing well-documented processes, continuous improvement, and customer satisfaction. Trust Rotor Clip for expertise, reliability, and proven quality across our rings, springs, and hose clamps.

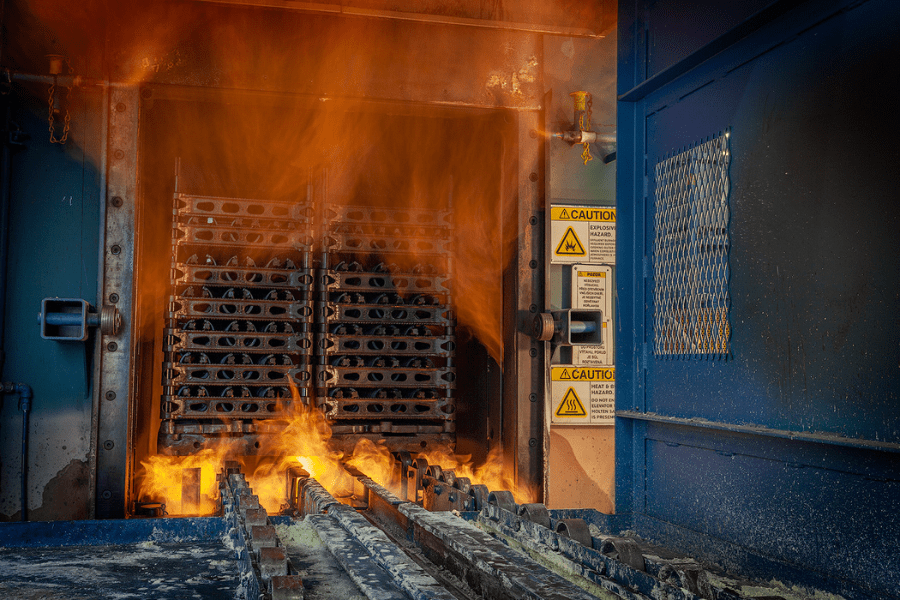

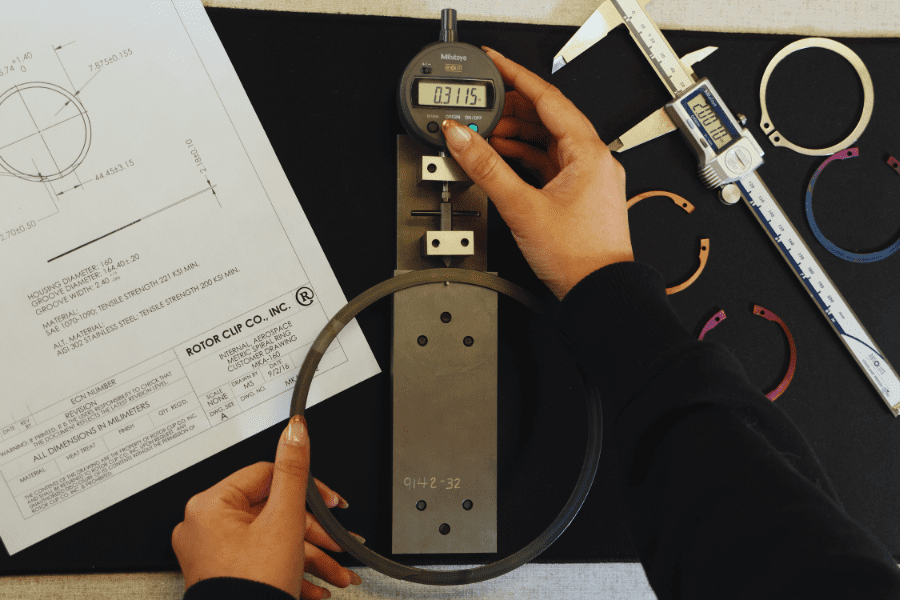

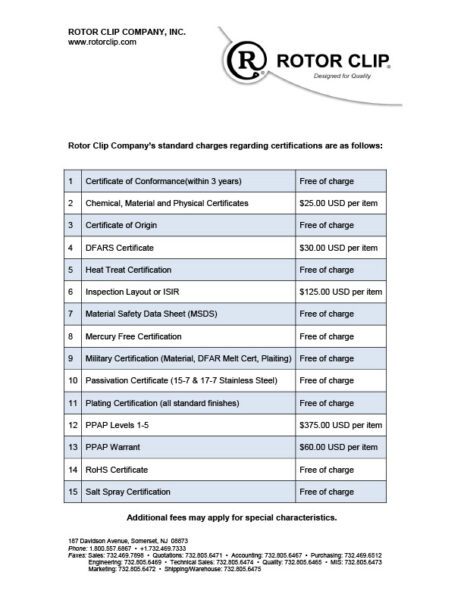

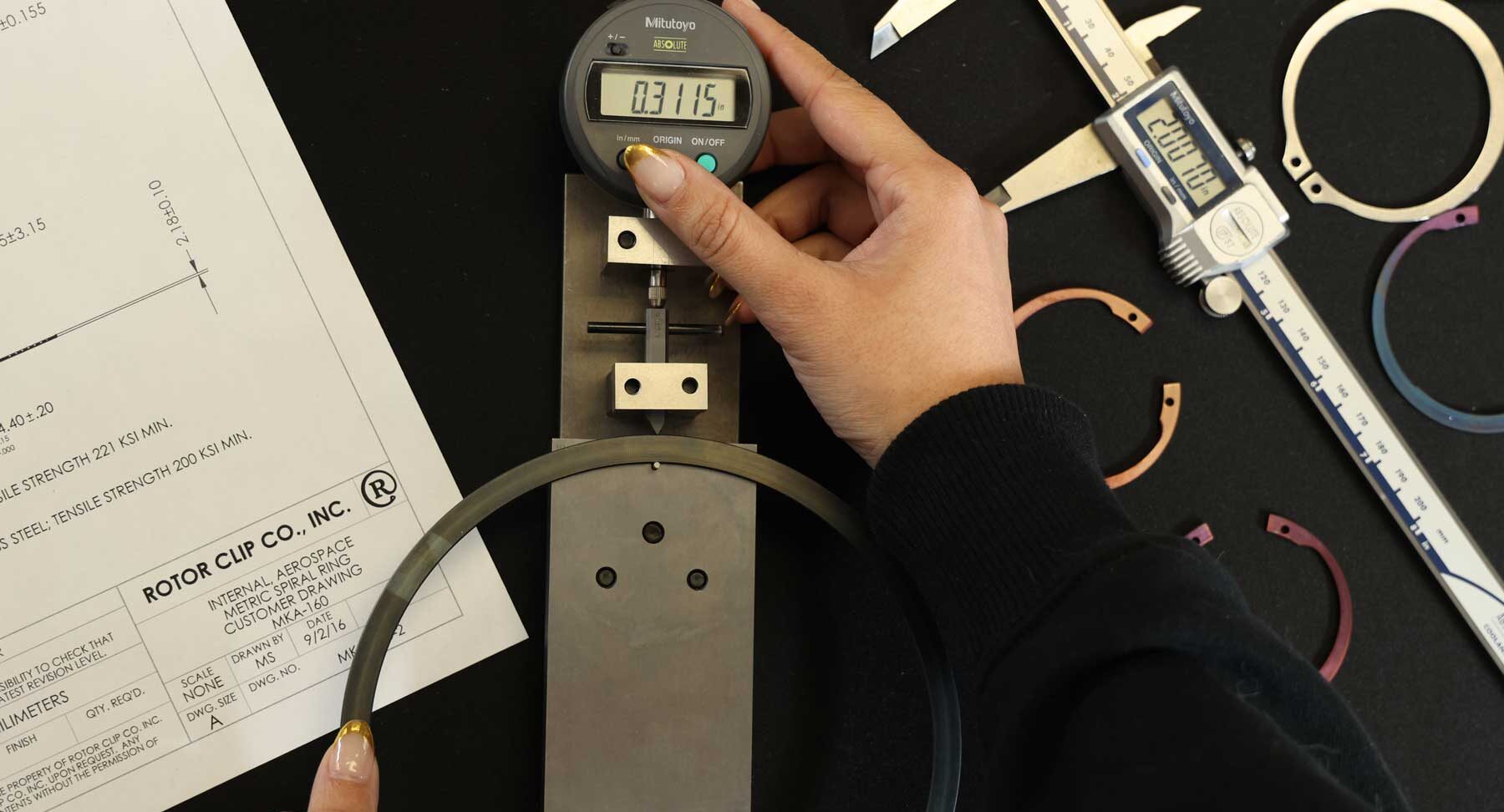

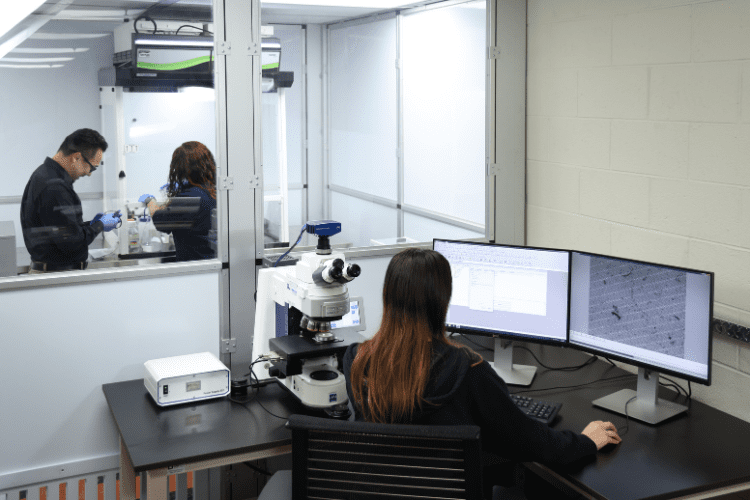

Our commitment to quality begins with meticulous inspections of incoming steel, ensuring it meets our standards for chemical composition, dimensions, and response to heat-treating. Our in-house laboratory conducts comprehensive product tests, pivotal for our Production Part Approval Process (PPAP) submissions and First Article Inspection Reports (FAIR). This lab also evaluates our manufacturing processes, such as plating, to ensure compliance with industry standards. Additionally, every product is traceable through lot numbers, providing a complete record from raw material to shipment, including inspection records.

ROTOR CLIP QUALITY POLICY

Our Quality Policy is defined and strongly driven by the following principles:

- Deliver quality products 100% on-time.

- Understand and meet customers’ requirements.

- Drive continual improvement in every process.

- Ensure competency, creativity, empowerment and accountability.