Step 1

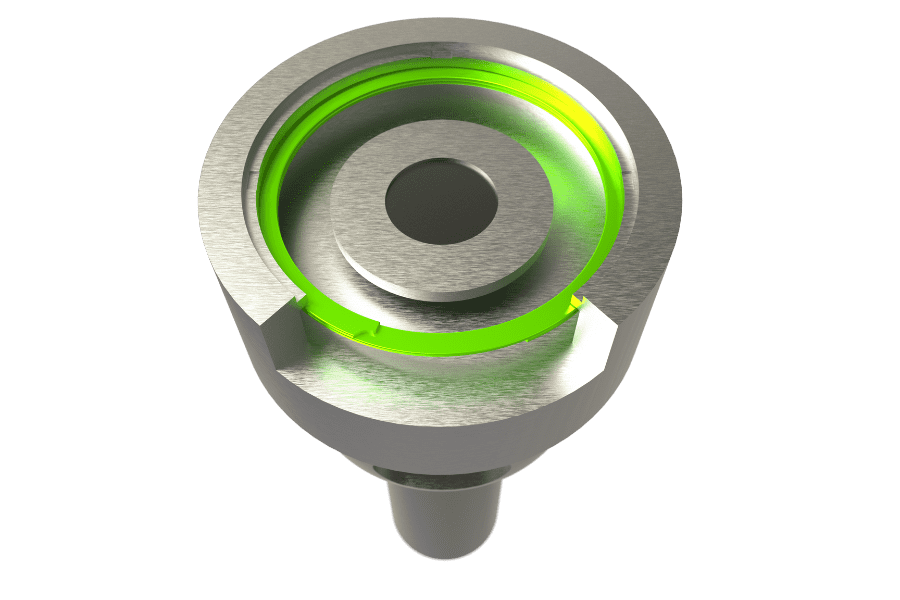

Locate the groove

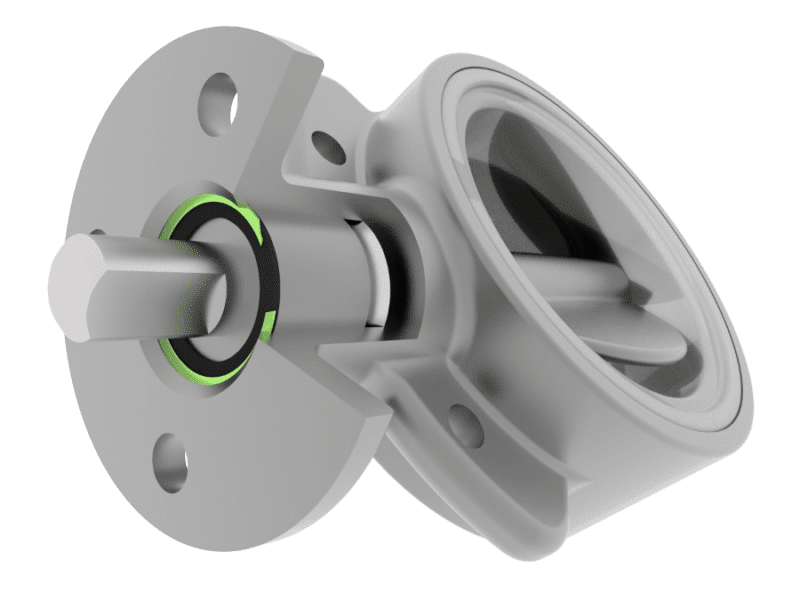

Spiral Retaining Rings, similar to Tapered Section Rings and Constant Section Rings, act as an artificial shoulder seated in a groove on a shaft or contained within a housing. Spiral rings are a coiled product, allowing for flexibility in sizing and alloy selection. Standard series are available from stock in carbon and stainless steel (302 & 316) with specialty alloys readily available.

Rotor Clip offers a range of ring families, each with unique advantages. Among them, spiral retaining rings stand out for their ability to provide 360° contact in multi-turn configurations, space savings without assembly lugs, and the flexibility of standard or custom configurations. Additionally, choosing spiral rings can result in cost savings, particularly in larger diameters, thanks to efficient scrap minimization techniques.

Spiral retaining rings are available from:

Spiral retaining rings are simple to install and remove. No special tools are required for assembly as the rings can be wound into the groove, however simple tooling allows for high-speed, automated assembly. For removal, spiral rings are provided with a removal notch or scallop, a basic screwdriver can be used to access the notch and wind the ring out of the groove.

Locate the groove

Guide Spiral Ring into groove on bore

Separate Spiral Ring to fit end into groove

Snap Spiral Ring into groove (use screwdriver if needed)

Installation Complete

Spiral retaining rings are commonly used in in the automotive, aerospace, medical device, and consumer electronics industries, among others, to secure components in place and withstand high rotational speeds and pressures.

Rotor Clip provides a variety of materials and finishes to suit any application.

Standard or custom, coiled or stamped, our rings are engineered for you. Send us your application requirements.