Materials

- Carbon spring steel (ST)

- Stainless steel – PH-15-7Mo (SS)

- Beryllium copper alloy #25 (BC)

- Stainless steel – DIN 1.4122 (SG)

- Phosphor bronze alloy #5218 (PB)

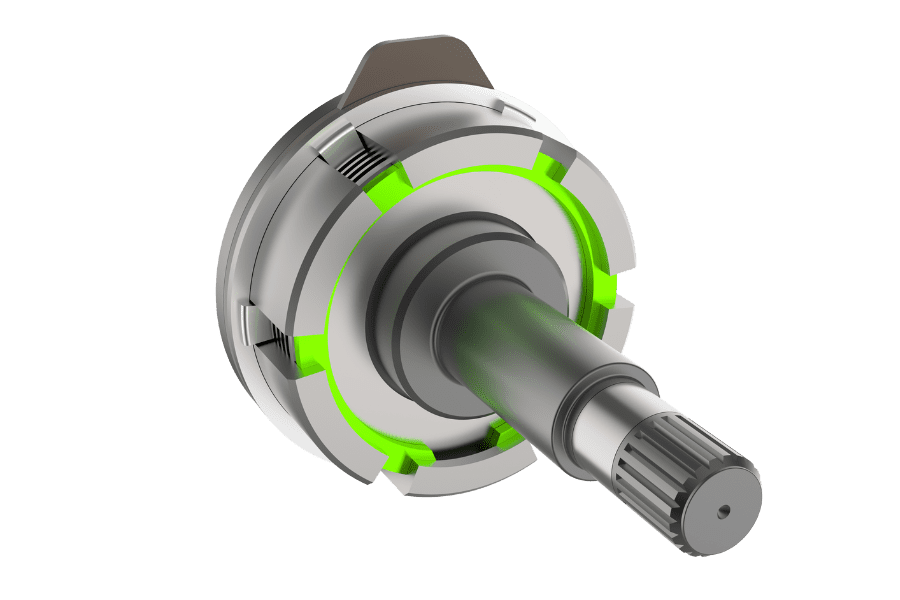

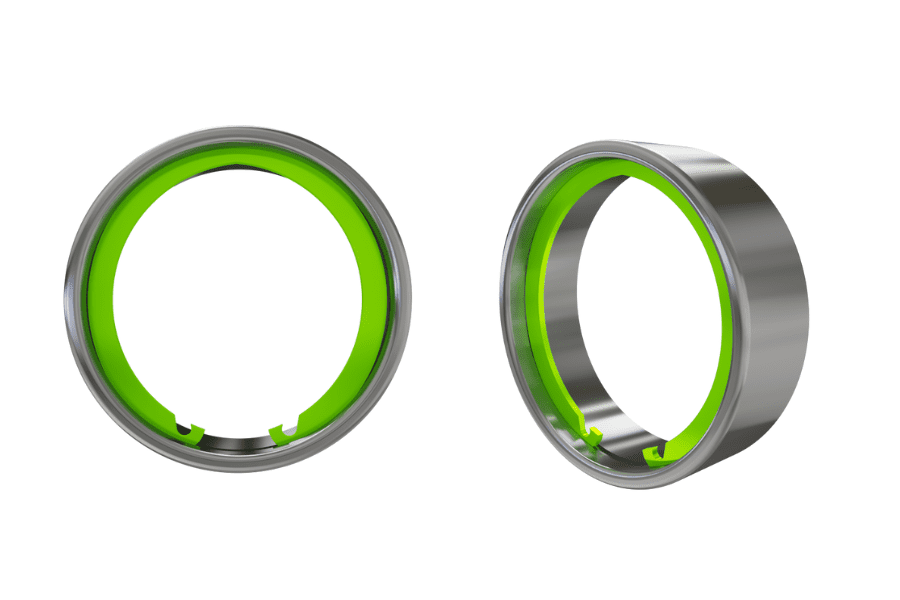

Constant Section retaining rings, commonly known as Snap rings, feature a uniform width along their circumference (radial wall), ensuring three points of contact with the groove. This lug-free design makes them highly effective in tight clearances or limited space. Rotor Clip Snap Rings are chosen for their robust cross-section, enhancing their ability to withstand impact loads effectively. They provide constant contact across a range of loads, with the shoulder securely holding assemblies in place.

Sizes available from:

Rotor Clip Constant Section rings / Snap Rings are available in a diverse range of materials to suit your unique needs. Whether you need stainless steel, beryllium copper, or phosphor bronze, our expert engineers utilize metallurgical expertise to ensure your snap rings provide exceptional strength and performance.

|

|

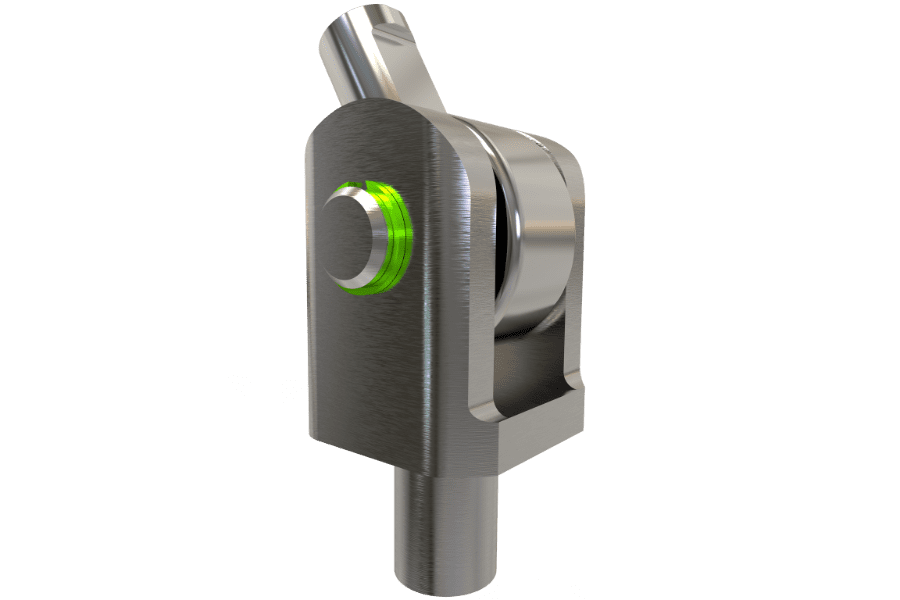

Constant section rings (snap rings) are extensively used in the Off-Highway, Construction, and Agriculture industries due to their heavy-duty, impact-loading capabilities. Common application examples include hydraulic cylinders, steering gear assemblies, brake systems, and other critical construction and agriculture equipment.

At Rotor Clip, we’re here to help you every step of the way to customize your constant section retaining rings. Whether you need adjustments in load capacity, rotational tolerance, end configurations, section thickness, or specific materials and finishes, we’ve got you covered. From start to finish, we ensure your rings meet your exact needs.

Constant section rings, also known as snap rings, are installed horizontally into grooves in housings or on shafts. They are designed for easy installation and removal, often without the need for special tools. Some constant section rings come with notches at the ends to facilitate simpler installation. Their straightforward application makes them a versatile choice for various industrial and mechanical uses.

A constant section ring (often referred to as a snap ring) is a metal fastener or retaining ring used to secure components within mechanical assemblies. This ring is designed to snap into a groove on a shaft or within a housing/bore. Snap rings come in various styles and sizes, including internal and external types, and can feature an open end to facilitate easy installation and removal. They are commonly made from carbon steel or stainless steel, but other exotic alloys can be used based on specific requirements.

Snap rings are installed using various methods depending on the application and ring series. We support our snap rings with a complete line of manual and pneumatic tools. Our engineering design team can assist you in designing custom application equipment for specialized or high-volume assembly.

Resources

Explore some of our most popular resources about retaining rings, snap rings, and circlips.