Rotor Clip’s double-disc grinding process makes hard-to-create tolerances possible

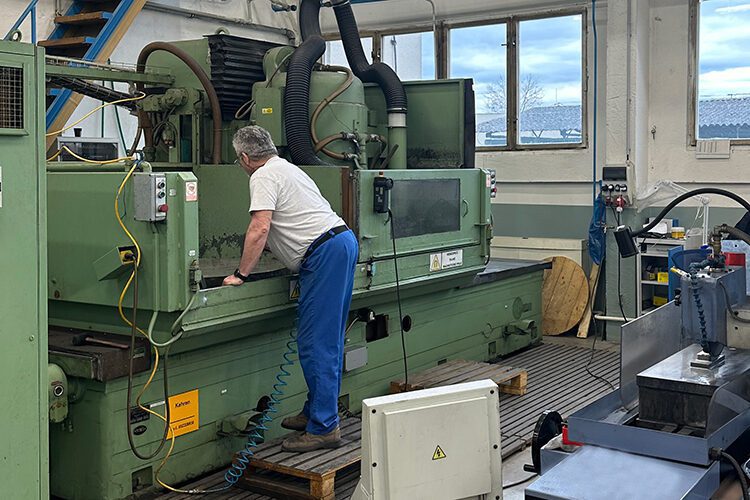

Rotor Clip strives to give its customers a perfectly fitting part. But because not every tolerance requirement can be met through standard processes, we can also custom-grind parts to precise tolerances using modern, efficient double-disc grinding equipment. This option is particularly desirable when a beveled part can’t fully compensate for endplay.

In this advanced grinding method, each workpiece passes through two grinding wheels at the same time to attain a dimensional tolerance that surpasses that of standard parts. In fact, Rotor Clip’s double-disc grinding process can achieve tolerances down to ±0.0127 millimeters (±0.0005 inches). Our double-disc grinding equipment can accommodate virtually any carbon steel stamped or wire formed retaining ring ranging in diameter from 15 millimeters (0.59 inches) to 199 millimeters (7.83 inches) and thicknesses from 1.5 millimeters (0.59 inches) and up.