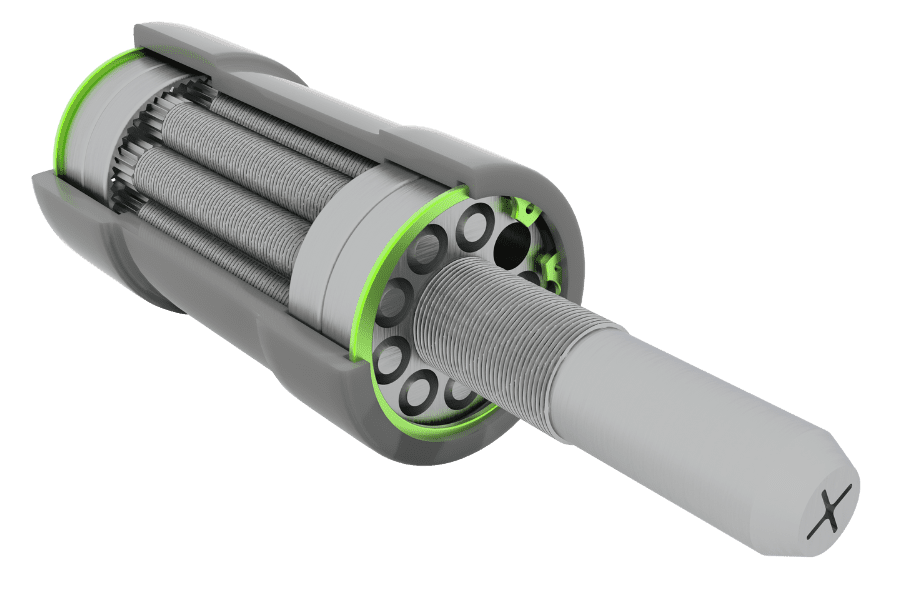

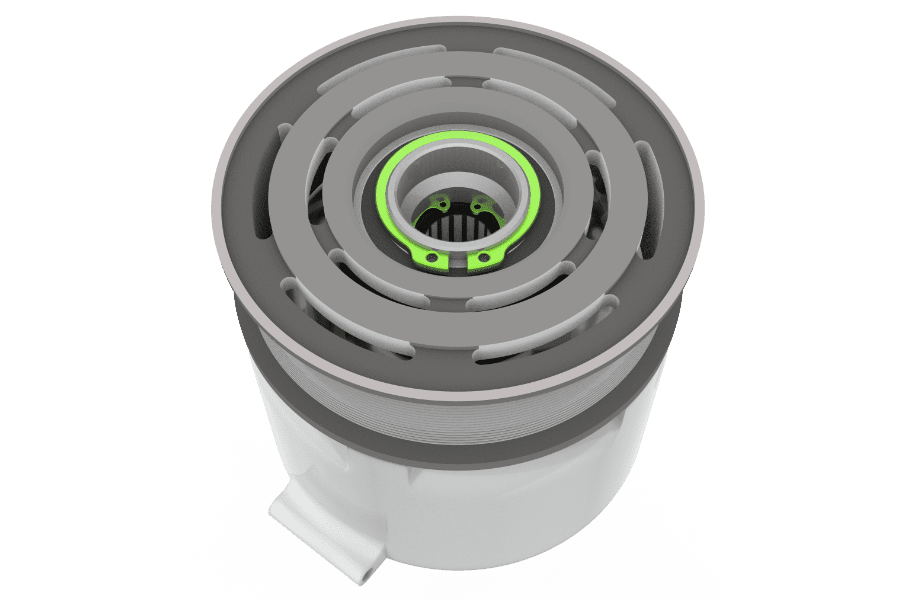

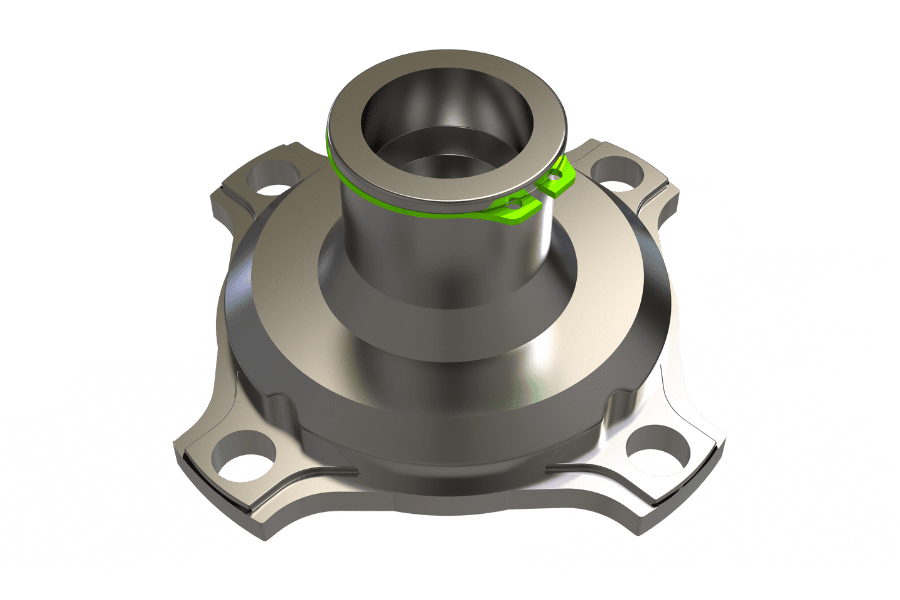

Beveled Retaining Rings

Beveled retaining rings serve a niche purpose beyond a regular circlip. Utilizing the ring’s spring characteristics within its own plane, the ring features a 15 degree bevel along the outer or inner edge to securely lock and wedge in place against the mating component. The corresponding groove profile ensures that the beveled wall bears the load. Precise calculation of groove location is critical to ensuring optimal performance.