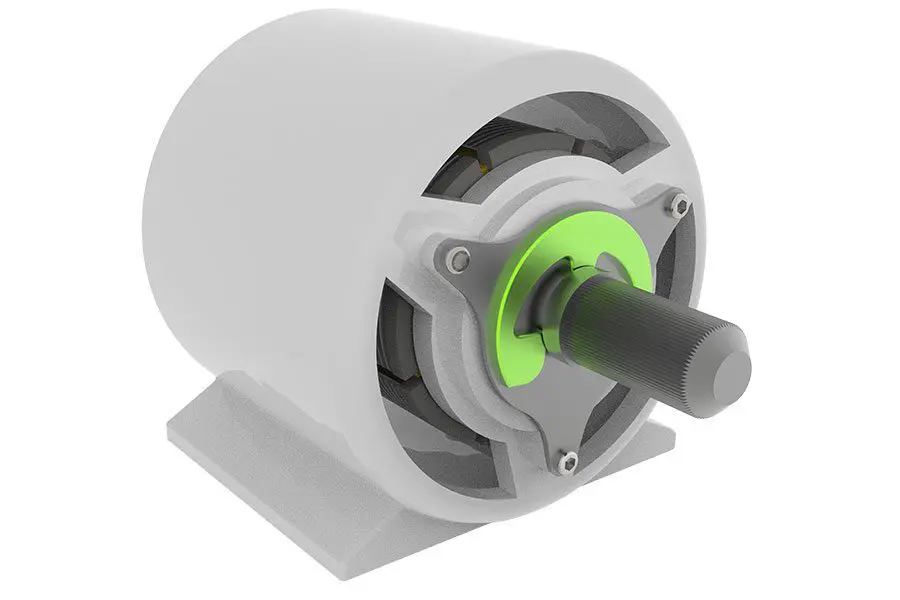

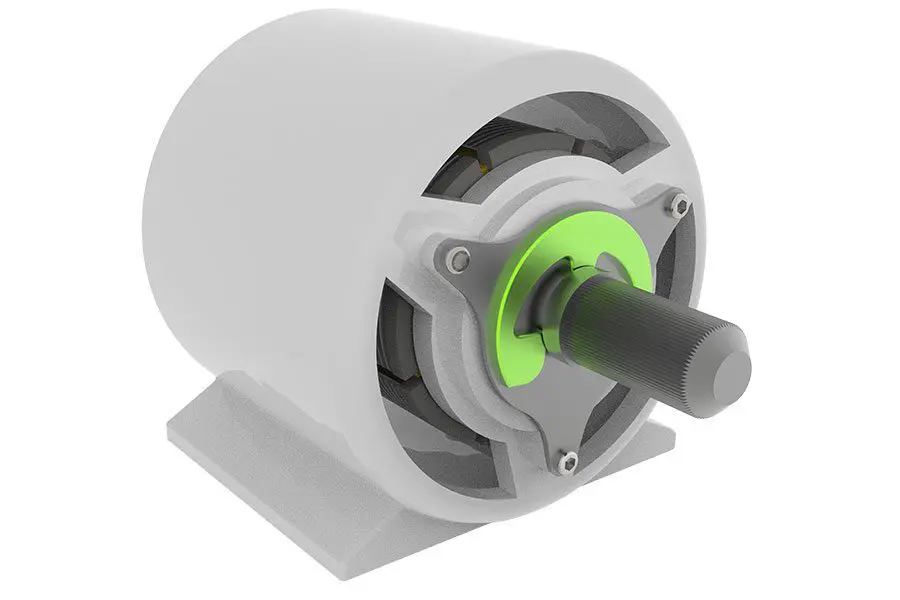

- Electric motors

- Gas springs and dampers

- Seating

- Door locks

- Brake systems

- Transmissions

- Transfer cases

- Filters

- Starters

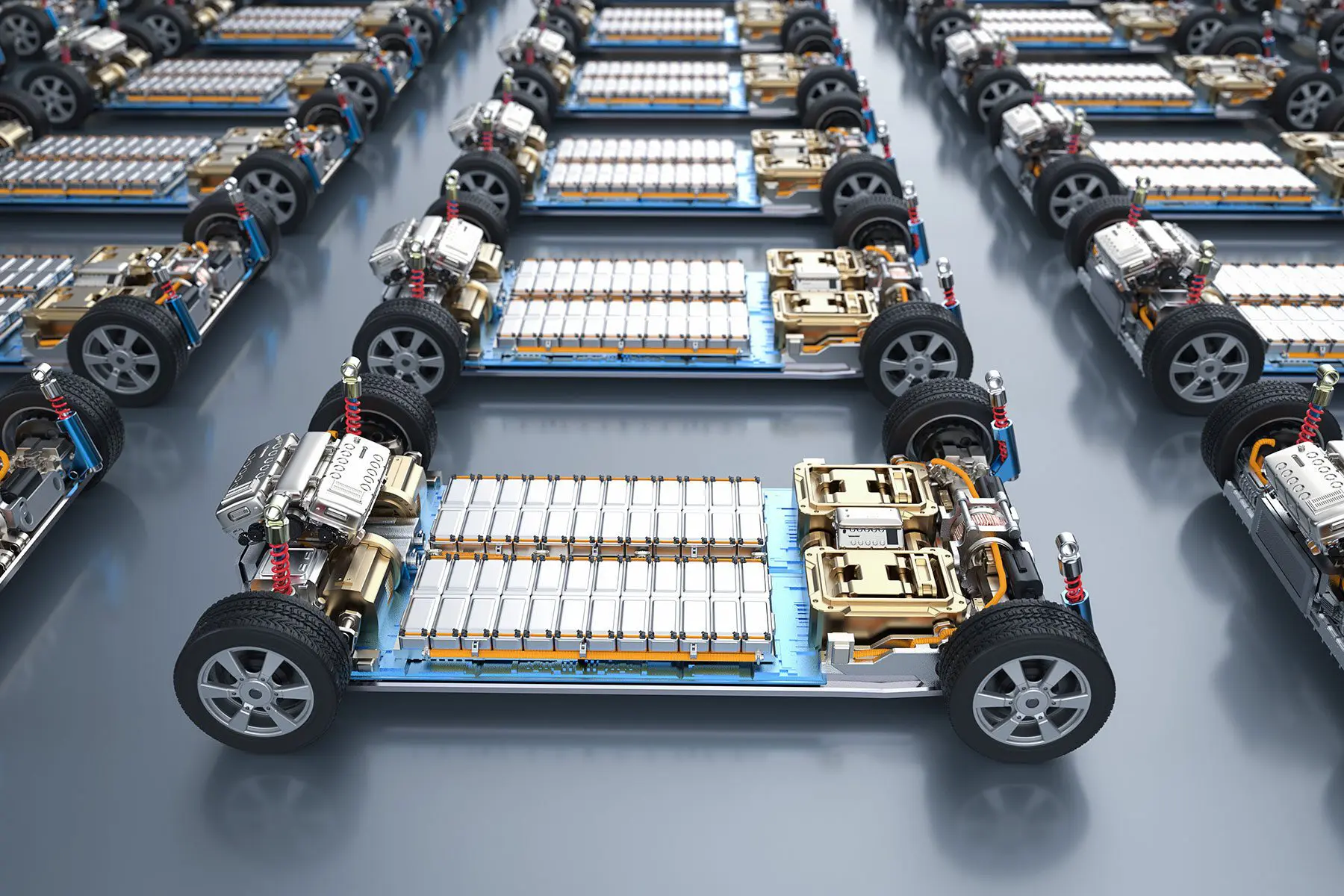

You’re accelerating towards the future. You can count on our partnership.

Commerce. Transportation. Safely getting families to school. You know that the parts no one sees are some of the most vital. You can’t let anything get in the way of excellence.

That’s why the automotive industry has trusted our full line of retaining rings, spiral rings, wave springs, and self-compensating hose clamps for over 65 years. We’re used in every part of the car, and can depend on wherever you use us.

From the electrification of vehicles to combustion engines, we’ve been there. We’ve worked with engineers like you. Keeping you driving is our passion.

All our products are manufactured in accordance with the relevant standards. Our commitment to them is at the heart of our mission. Rotor Clip is TISAX certified and registered to IATF 16949, ISO 9001, ISO 14001, ISO 13485 & AS9100.

Many materials and finishes are available to suit one’s requirements, and Rotor Clip’s knowledgeable sales engineers are available to assist designers in selecting which options are best for their project.

Rotor Clip retaining rings, wave springs and hose clamps are made from high-quality, high-strength materials and finishes. Parts are manufactured from carbon steel as standard with no extra charge, but with warehouses stocked full of raw materials including stainless steel — which provides SAE-grade reliability and protection — and several specialty materials, we have material options to withstand even the harshest automotive conditions.

From engine to trunk, Rotor Clip is where you need us to be.

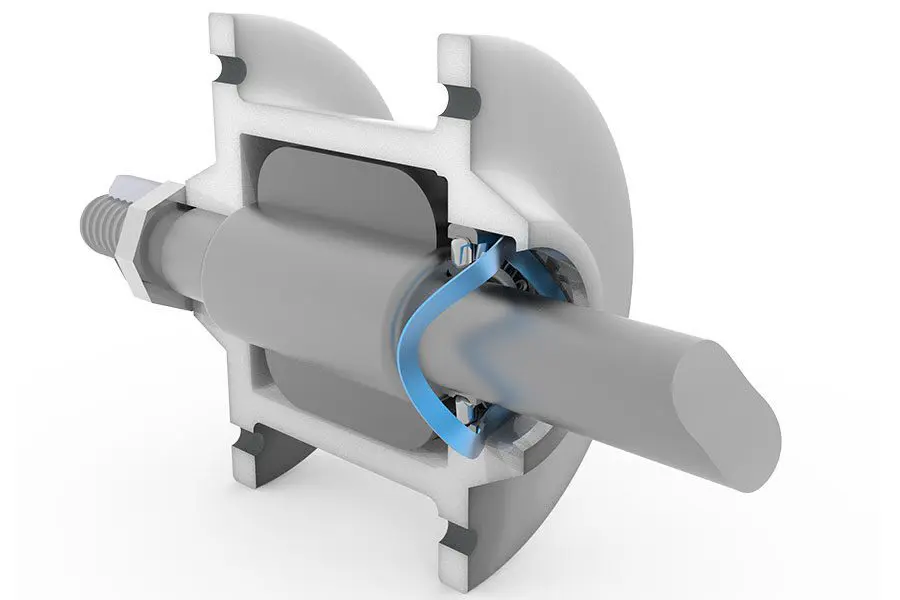

Some cars require standard retaining rings and wave springs, others need parts to be custom made. No matter what, you have to make sure you have the right ones in your design. There’s a lot riding on it.

As automotive design engineers work to innovate and streamline their industry, our own team of dedicated engineers work in concert with them to develop the most cost-effective and functional components for their applications.

If the solution doesn’t yet exist? We’ll make it. Our one-stop shop allows us to customize, design, prototype and manufacture scaled production volumes, with no interference in your work.

It’s how we’re more than parts. We’re a true partnership.

Featuring alternating inactive (flat) and active (waved) turns, the InterShim™ Wave Spring is engineered for reliable performance in demanding applications. This design withstands torsional loads and high acceleration, ensuring precise rotational movement and reliable performance.

Rotor Clip manufacturers all styles of rings, however balanced tapered section retaining rings are a cost-effective option for high-speed applications which require a low balance/noise in the assembly.

No matter where you are in your build, our team can get you the right parts. Our reputation is your assurance.