- Carbon steel (standard)

- 17-7 Stainless Steel

- Special Material Grades:

- Stainless – AISI 302

- Stainless – AISI 316

- Stainless – A286

- Inconel® X-750

- Elgiloy®

- Hastelloy® C276

- Beryllium-copper

- Phosphor-bronze

Why settle for ordinary springs when wave springs offer compact design, greater efficiency and superior performance in less space?

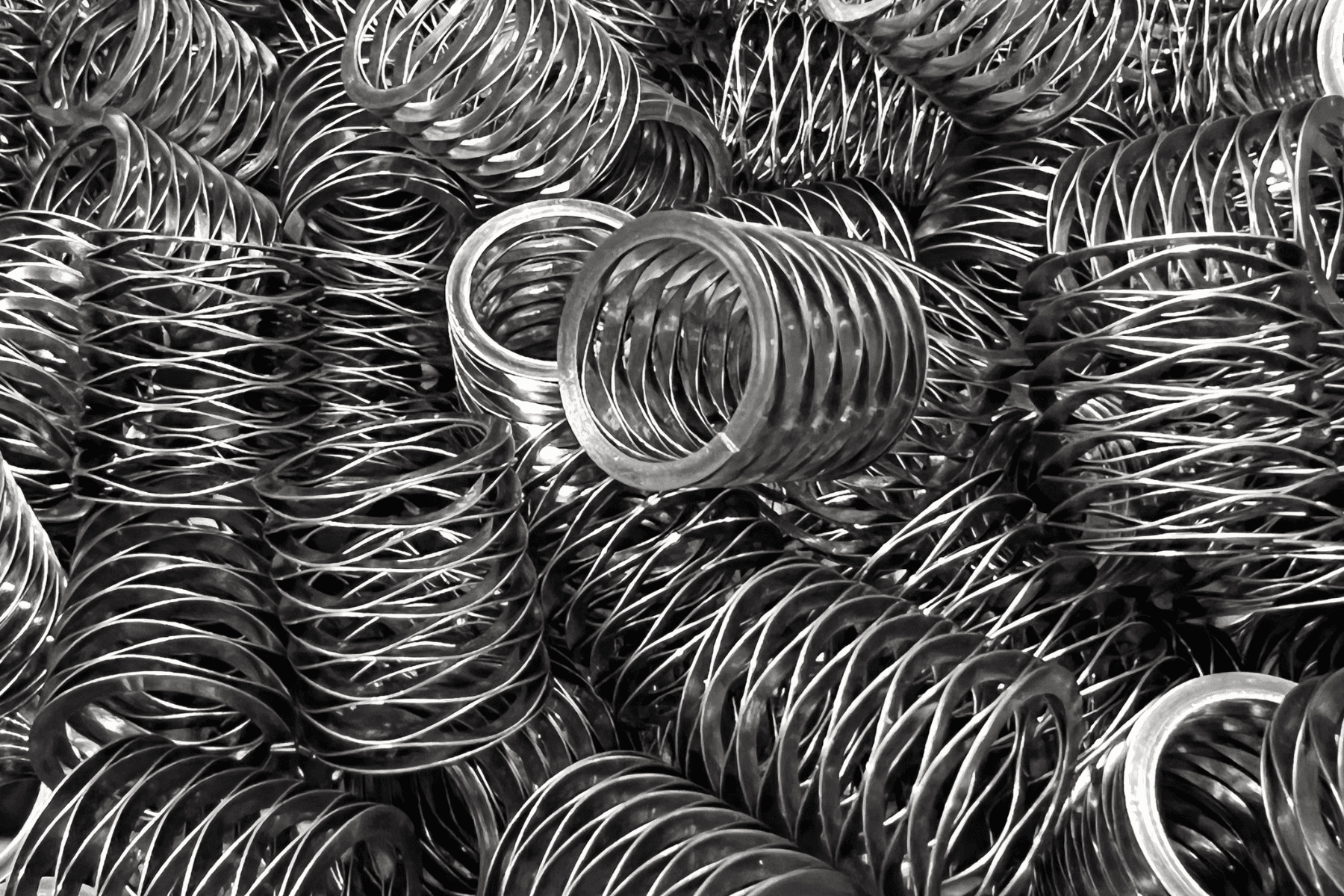

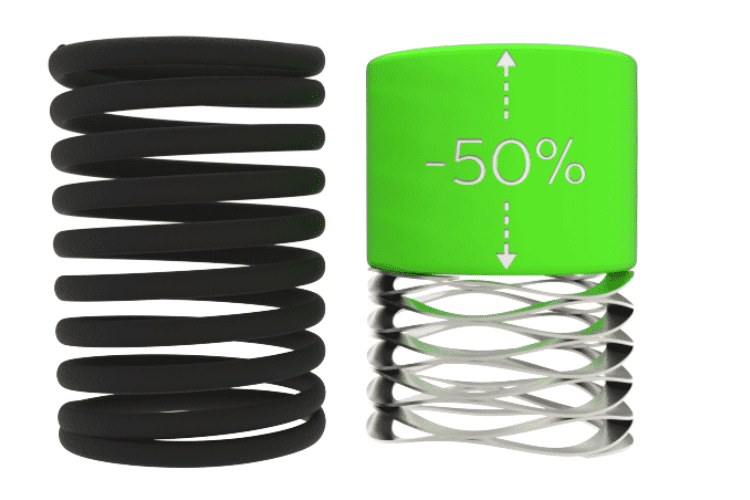

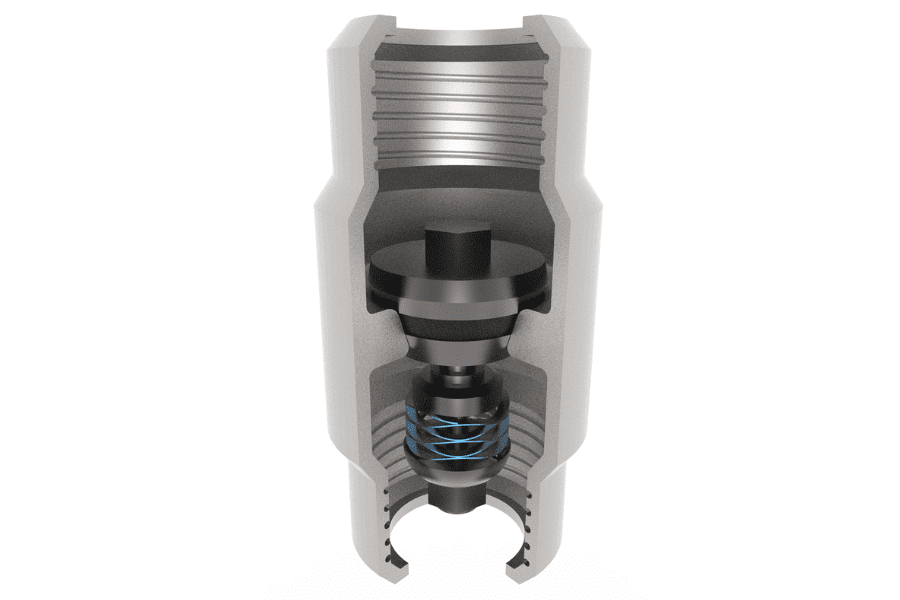

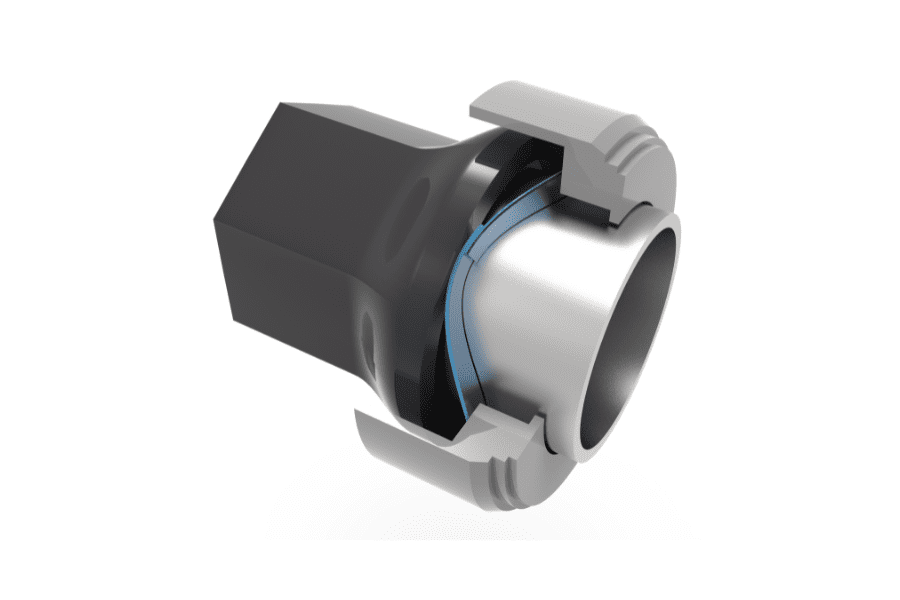

A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip Wave Springs can make in your applications today.

Choosing the right type of wave spring involves considering factors such as load capacity, cycle life, operating heights, and spring rate. Each type of wave spring is engineered with specific features to address your diverse needs. Explore the different wave spring styles we offer below.

If our standard wave springs don’t meet your needs, we’ll work closely with you from prototype to production to create a custom solution. Whether it’s adjusting material thickness, number of waves or turns, or modifying end configurations, we’ll make sure you get the perfect wave spring for your application.

To accommodate for unique loads or cycle life, types of modifications include:

At Rotor Clip, our team of experienced engineers is always ready to help tackle your most complex ring and spring challenges. Whether you need assistance with part selection, alloy choices, or assembly guidance, we’re here to work alongside your team and provide expert support, ensuring you get the right solution for your application.

Rotor Clip offers a range of standard and specialty materials for wave springs, from stainless steel to exotic alloys like Inconel, Elgiloy, Hastelloy and more, to handle even the harshest of environments. Our experienced engineering team offers expert guidance to help you choose the right wave spring based on load requirements, environmental conditions, and space constraints, ensuring optimal performance and durability.

|

|

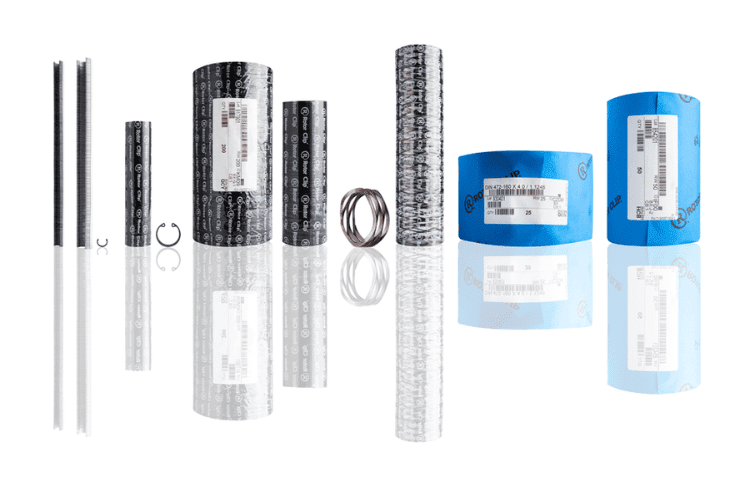

Rotor Clip’s service extends beyond manufacturing. We ensure your wave springs are packaged securely to arrive in optimal condition, with quantities and weights designed for easy handling and streamlined installation. Our packaging uses fully recyclable materials, helping you meet cost, scheduling, and sustainability goals.

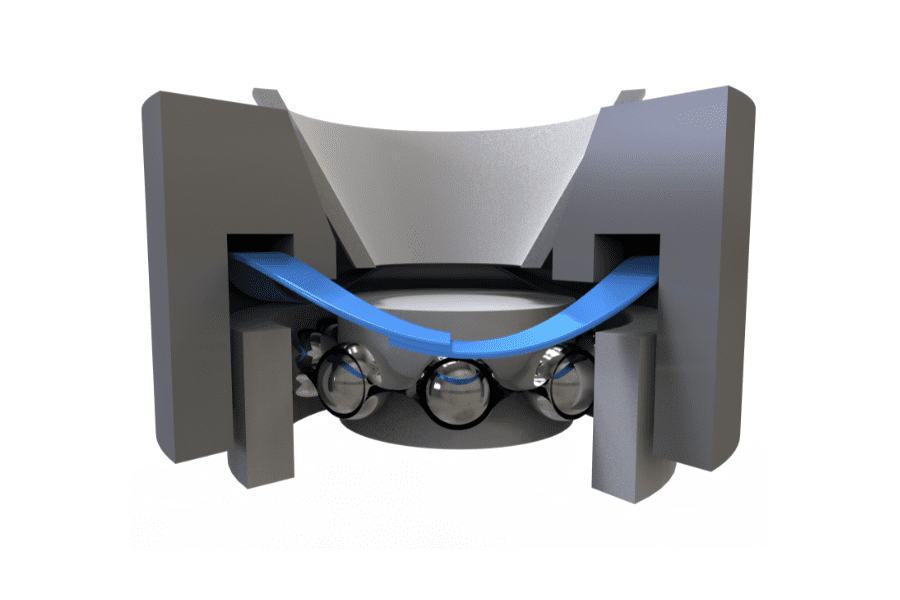

Rotor Clip Wave Springs offer a simple solution by replacing multiple components, simplifying installation, and reducing the risk of errors. Wave springs deliver the same force and deflection as coil springs, but with the added benefits of space and weight savings. Watch our latest video to see how a single wave spring can be used to optimize this transmission assembly!

Wave springs can be found in a wide range of industries, including medical, aerospace, automotive, and beyond. Here are some examples.

A wave spring is a unique type of flat wire compression spring with a distinctive waveform-like design. Think of it as a spring that compresses and expands in a wave-like motion, similar to the natural waves in water. Unlike traditional coil springs or disc springs, wave springs are engineered to be more compact while still delivering efficient compression and deflections.

Wave springs deliver up to 50% tighter force tolerances than standard wave washers and offer more consistent performance. They maintain a more predictable loading throughout a wider range of movement, making them a more reliable choice for. Rather than stacking wave washers, a single wave spring can be used as a single part solution, simplifying assembly and reducing room for errors.

Wave springs generally have lower fatigue rates compared to traditional coil springs, meaning they tend to last longer. When used correctly within their designed deflection range, wave springs can outlast coil springs. They also take up about half the space, which can help reduce both weight and space in your assembly—important factors that contribute to their longer lifespan.

There are several ways to address this challenge. Depending on the application and environment, you could increase the wire thickness to handle higher loads. If a thicker wire isn’t feasible for the spring size, consider using a nested wave spring, where multiple layers are coiled together to distribute the load. Alternatively, increasing the number of waves can also boost load capacity. Lastly, selecting a different material may provide the necessary stiffness and durability for higher force requirements.

When choosing the right wave spring, it’s important to consider factors like the application type, available space, and load requirements. Different types of wave springs, such as Single-Turn, Multi-Turn, or Nested, offer unique benefits for various applications. For example, wave springs designed for high-acceleration environments like EV applications can also be beneficial in similar use cases. Rotor Clip’s engineers can assist you in determining the best option based on your specific needs. Contact us now, and we’ll help guide you to the right solution.

The InterShim™ wave spring is engineered for reliable performance in demanding applications. Featuring alternating inactive (flat) and active (waved) turns, this patented design withstands torsional loads and high acceleration, ensuring precise and reliable performance when rotational movement is present.

Discover the benefits of the InterShim™ now

Traditional Belleville washers or disc springs often fall short in delivering precise, repeatable loads and accurate positioning. Rotor Clip Wave Springs eliminate misalignment and ensure consistent performance, making them the ideal replacement.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.